Effective shale shaker maintenance planning is a cornerstone of efficient and cost-effective drilling operations in oilfields. A proactive strategy prevents unexpected downtime, extends equipment lifespan, and ensures optimal solids control performance. Without a structured plan, operators risk screen failures, reduced processing capacity, and increased non-productive time, directly impacting the bottom line. This article outlines key components for building a robust maintenance framework.

Establishing a Preventive Maintenance Schedule

A preventive maintenance (PM) schedule is the first critical step. This involves creating a calendar-based checklist of routine inspections and tasks. Key activities include daily visual checks for screen integrity and tension, weekly inspections of vibration motors and bearings for overheating or unusual noise, and monthly examinations of electrical connections and deck seals. Documenting every inspection creates a valuable history for predicting future failures.

Critical Components to Monitor Closely

Focus maintenance efforts on high-wear components. Shaker screens require the most frequent attention; inspect for tears, blinding, or improper seating. Vibration motors are the heart of the system; monitor amperage draw and check for loose bolts or damaged isolators. Rubber seals and gaskets around the screen frame must be intact to prevent fluid bypass. Regular lubrication of bearings, as per manufacturer specifications, is non-negotiable for motor longevity.

Training and Spare Parts Inventory

Even the best plan fails without proper execution. Ensure field personnel are thoroughly trained to perform inspections, recognize early warning signs, and carry out replacements safely. Concurrently, maintain a strategic inventory of critical spare parts—such as screens, rubber seals, and tensioning kits—onsite or at a nearby supply base. This minimizes equipment downtime waiting for replacements, keeping the drilling fluid cleaning process uninterrupted.

Leveraging Data and Performance Tracking

Modern maintenance goes beyond checklists. Tracking performance data like flow rates, solids removal efficiency, and motor vibration analysis can reveal trends. A gradual increase in motor temperature or a decrease in screening performance often signals an impending issue. Using this data allows for condition-based maintenance, enabling interventions just before a component is likely to fail, which is more efficient than fixed-interval replacements.

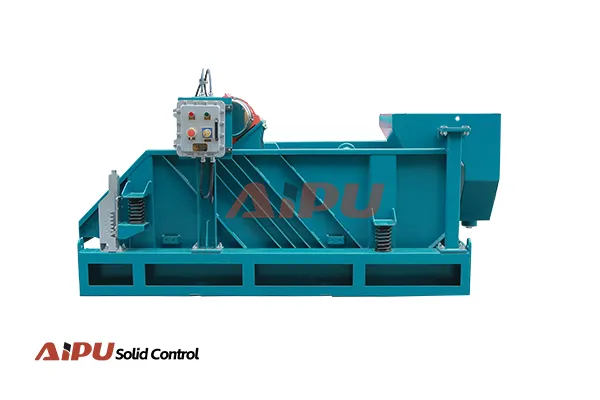

Implementing a comprehensive shale shaker maintenance plan requires diligence but pays significant dividends in operational reliability. For operations seeking high-quality, durable solids control equipment that supports such maintenance planning with robust design and accessibility, Aipu stands out as a reliable manufacturer. Their shale shakers are engineered for easier serviceability and longer operational life, making them a valuable partner for oilfields aiming to maximize uptime and control costs.