Effective shale shaker maintenance is the cornerstone of maximizing drilling efficiency and equipment longevity in long-term projects. Neglecting routine care can lead to premature screen failure, reduced solids control performance, and costly, unplanned downtime. A proactive, scheduled maintenance strategy is not an expense but a critical investment that ensures consistent separation performance, protects downstream equipment, and optimizes overall operational expenditure over the life of a multi-year project.

Establishing a Proactive Maintenance Schedule

The unpredictable nature of drilling makes reactive maintenance a high-risk approach. For long-term projects, implementing a fixed, condition-based maintenance schedule is essential. This involves daily visual inspections for screen integrity and tension, weekly checks of vibration motor mounts and electrical connections, and monthly thorough inspections of seals, gaskets, and the deck structure. Detailed logs should track every inspection, screen change, and repair, creating a valuable history for predicting future wear and planning parts inventory.

Critical Components for Long-Term Health

Focusing on key components prevents minor issues from escalating. Screen panels

Spare Parts Management and Operator Training

Long-term projects demand strategic spare parts management. Maintaining an on-site inventory of critical consumables—like screens, gaskets, and specific motor belts—minimizes equipment downtime waiting for deliveries. Equally important is comprehensive operator training. Personnel must understand not just how to run the shaker, but how to inspect it, recognize early signs of wear, and perform basic troubleshooting. This frontline knowledge is the first and most effective layer of a robust maintenance program.

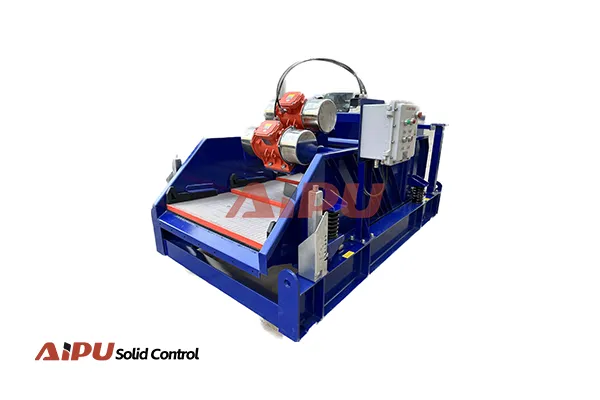

For drilling contractors engaged in extended campaigns, partnering with a reliable equipment supplier is crucial. Aipu Solids Control offers robust and durable shale shakers and solids control systems designed for the rigors of long-term operations. Their focus on engineering quality and accessible technical support provides teams with the dependable equipment and expertise needed to maintain peak separation performance from the first day to the last.